COLOP expands its range of services

Plastics expertise now available as a service

As a stamp manufacturer, we have been active in production for decades, hence building up profound expertise when it comes to processing plastics. And it is precisely this knowhow that we now want to actively offer on the market for other companies!

We are pleased to announce that we will be expanding our range of services. Under the motto "Everything from a single source – from the idea to the finished plastic product", we are officially entering the field of product development and manufacturing of plastic parts for other companies. "With this expansion, we are demonstrating that COLOP is much more than just a manufacturer of stamps," explains our Managing Director Christoph Skopek. ‘We are combining our expertise from different areas to create complete solutions that guarantee the highest quality and efficiency."

Our own production has always been proof of our precision and our modern machinery. We have now decided to offer this accumulated experience directly to the market and create clear added value for our future business partners.

Complete solutions from a single source

COLOP offers a wide range of services related to plastics manufacturing in the future:

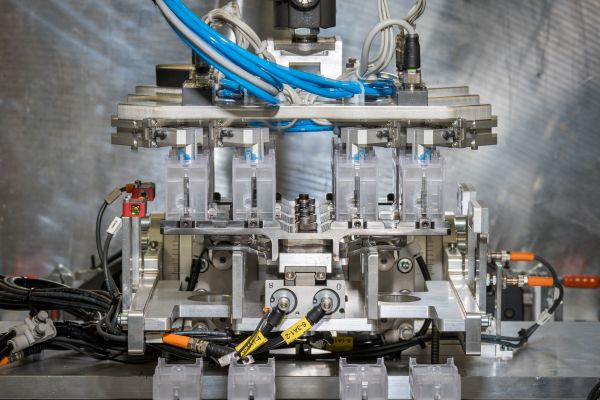

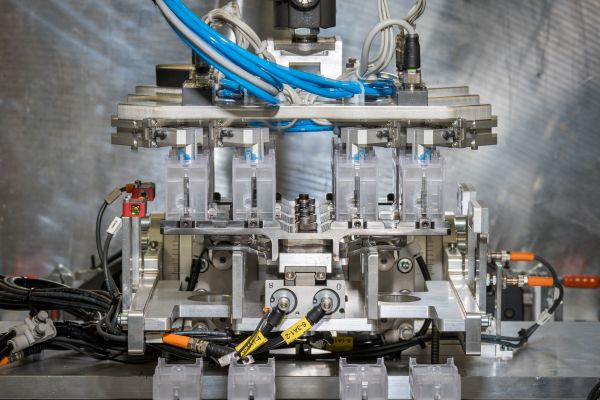

- Injection moulded parts manufacturing using state-of-the-art machine technology

- Precision parts manufacturing for the most demanding requirements

- Small series production – ideal for testing and market launches

Our strengths – your advantage

- In-house development and prototyping of your product requirements

- Design of injection moulding tools, including simulations

- Sourcing of additional components via an international network

- Customised automation solutions

- Contract assembly of your product through to finished packaging

- Development and sourcing of suitable packaging

- Support with logistics and shipping with international experience

Innovation for the future

“We have decided to offer our decades of experience in the manufacture of plastic parts directly to the market, thereby creating clear added value for our future business partners”, explains Christoph Skopek. "This enables even companies without their own plastics expertise to produce high-quality products in manageable quantities. Many complex metal parts can be replaced by plastic – with advantages in terms of weight, cost and corrosion resistance, for example."

The company is thus responding to the growing demand for flexible, efficient and high-quality plastic solutions. We are very much looking forward to the new projects and the opportunity to put our manufacturing expertise to work together with new partners!

Do you have an idea that you would like to realise with us? Get in touch!